Spring Break: Factory Tour Edition

We've just begun a two-week spring break staycation, and I've rarely been so grateful to live in such an interesting city.

Wyatt is keenly interested in learning how stuff gets made. And he is even more interested in a manufacturing process if it requires lots of heavy machinery and many delivery trucks with forklifts. We spend so much time talking about (and speculating about) how stuff gets made that I recently started toying with the idea of taking him on some factory tours.

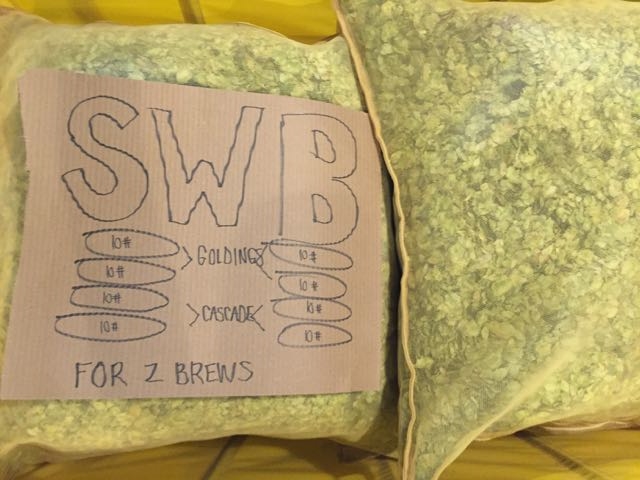

To be honest though, when the idea of factory tours occurred to me, I was probably thinking about how much I love factory tours and hoping Wyatt was old enough to (1) behave and (2) learn something. I guessed that he was, and I tested my guess during February break when we took our first tour. We started with a beer factory, Anchor Steam Brewery. After years of driving past it and speculating about what it must be like inside, I figured, why not find out? Wyatt was overjoyed when I told him we were going to the brewery, and once there, he was totally perplexed as to why there weren't any other kids on the tour. I'm pretty sure that we were the only people in the group who were more interested in the tour of the facility than the extremely generous beer tasting at the end.

Since that successful factory tour, I've been researching and contacting San Francisco manufacturing companies to see if Wyatt and I can come and see how they do their work. I have yet to find a chocolate factory that will have us, and an electric motorcycle company declined my request because of their production schedule, but disappointments aside, how lucky are we that our first week of break is bookended by a tour of McRoskey Mattress Company on Monday, and Timbuk2 on Friday? Just based on the McRoskey tour, we are incredibly lucky.

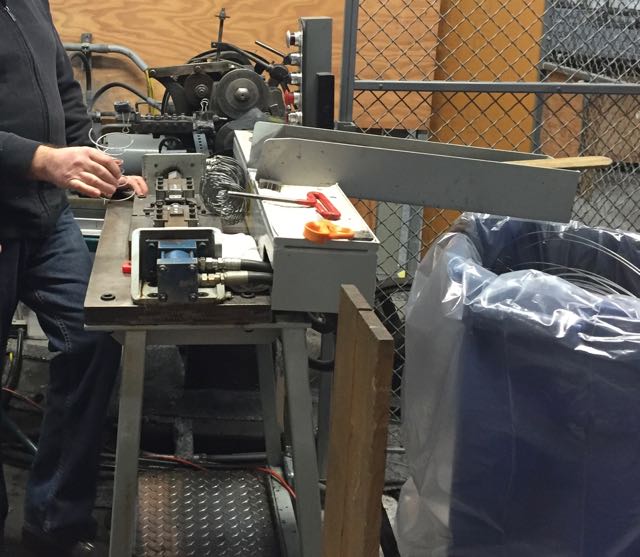

The McRoskey tour was fabulous. We were six people (three adults, two kindergarteners and one teenager) on the tour, and we followed McRoskey's entire process of building a mattress, from the bolts of fabric, spools of wire, metal fittings, and what looked like bales of cotton, to the end product: a handcrafted mattress that got tufted as we watched. We also saw how the box springs are made. Our guide, Robin, was incredibly knowledgeable and kept everyone's interest. Possibly even more impressive were the workers and craftspeople we saw creating these beautiful mattresses—every single person was simultaneously focused on their work and incredibly welcoming.

First we saw the sewing room, then we headed to watch spring-making and spring-fastening. We saw the cotton, wool, and other layers that go into the mattress and watched it get sewn together. We watched them build box springs. And then we watched as different people made two huge tufting machines do their magic.

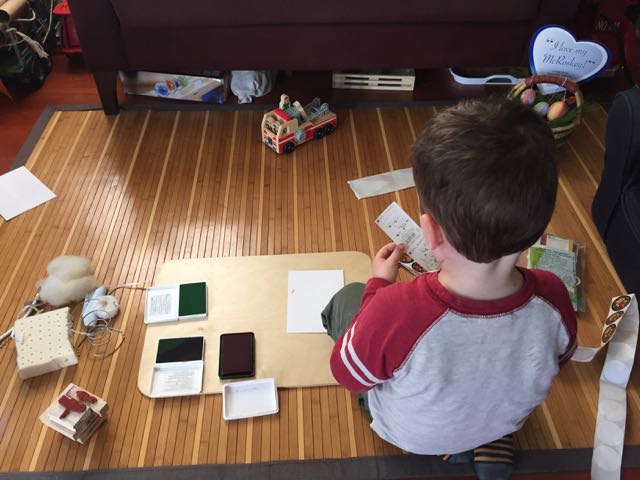

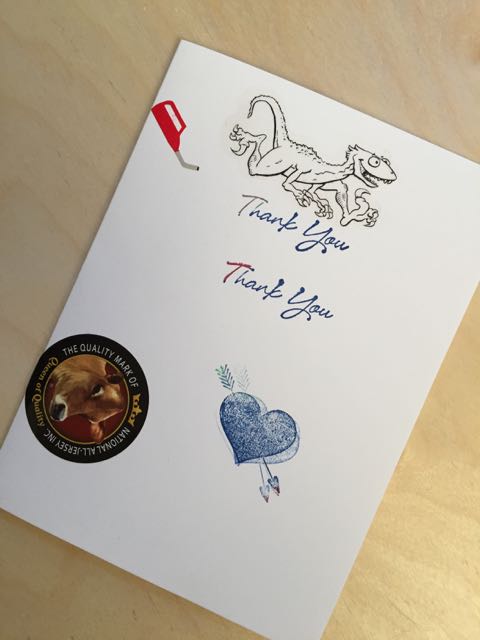

Wyatt and I drafted his "Thank You For The Tour" note this afternoon. He worked on the card at his little project board, next to his haul of many of the mattress manufacturing treasures that Robin had given him. Among other things, he asked me to write, "I think that if I worked at your mattress factory, I would want to be the person who folds and weighs the fluffy cotton . . . I liked how . . . you asked everyone if they were available to show us how all the machines worked."

I'm so glad I'm not the only one who loves factory tours.